QVALON for Supply Chain

- +5%increase in sales Learn more

- +20%increase in staff efficiency Learn more

- to 20%savings in compensation Learn more

- +25%increase in customer loyalty Learn more

QVALON Helps With

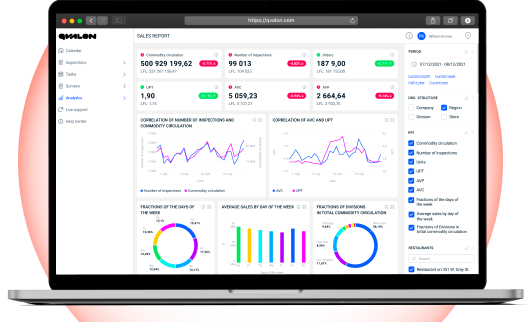

Key metrics

Stay on top of crucial reports that reflect the business health of your organization, such as inspection reports (inbound & outbound), fleet downtime, transportation losses, delivery times, client satisfaction, operating expense, and more.

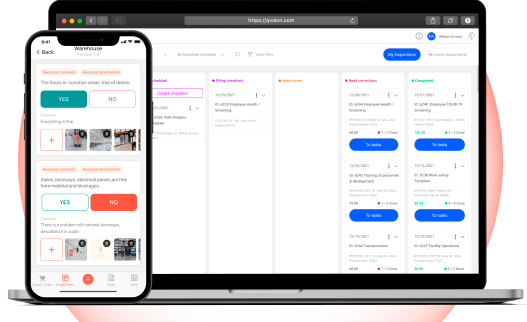

Fleet maintenance

Move on from checklists, reports, spreadsheets and notices in hard copies. Do online review of actual operational quality against standards so as to assist teams to overcome deficiencies. Digital risk analysis and equipment audits allow quick execution of

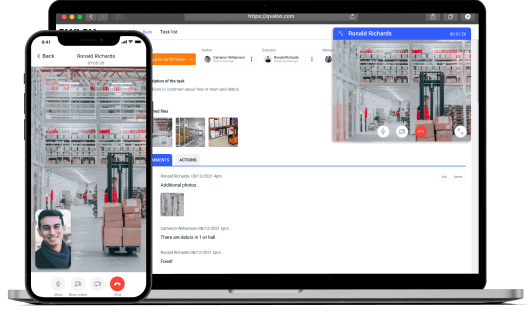

Communications

Maintain close coordination between drivers, warehouse teams and backroom staffs that are usually spread over large geographies. Keep teams updated on any recent revisions in local policies or protocols.

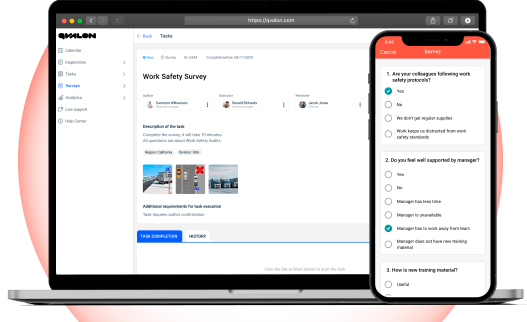

Employee training

Train new employees on safety, equipment maintenance and handling, risk analysis, material storage, and more. Digitally source knowledge from staff regarding the challenges they face in fulfilling their roles and suggestions on how tasks can be executed b