Qvalon Blog article content

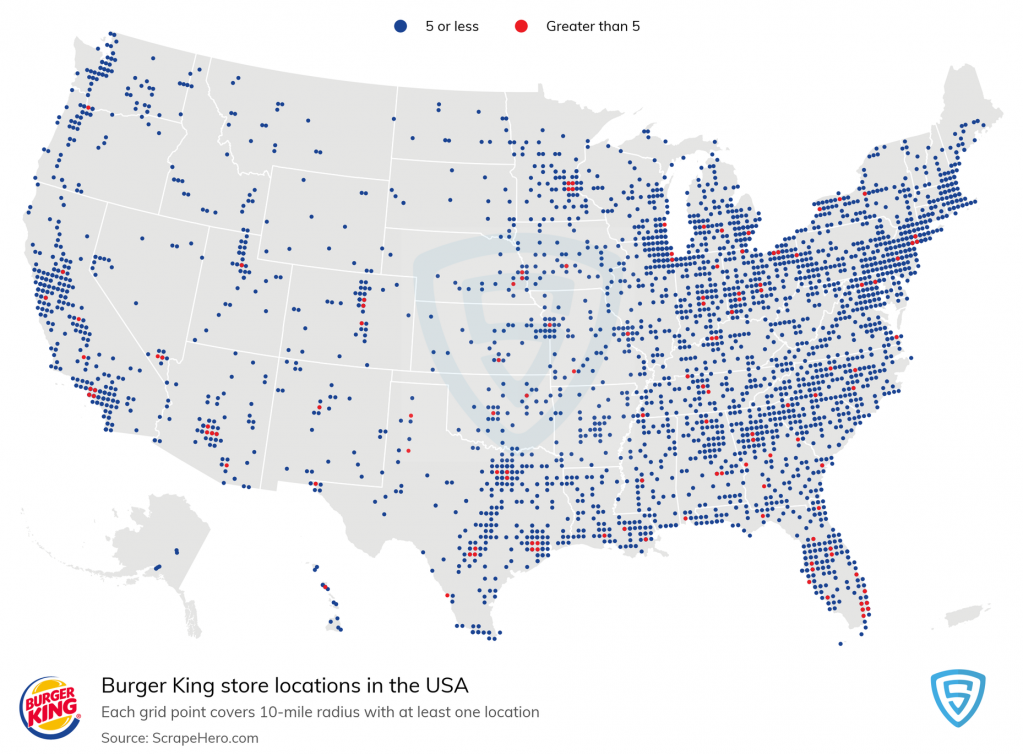

Big company

In a country divided into nine time zones, with daylight saving time (DST) observed in most, not all of its regions, maintaining optimum cleaning performance across all outlets in such varied geography can be challenging.

A few of the common, yet major challenges are,

-

While some of the issues are faced by all outlets, most of the concerns are specific to each location or outlet. The nature of these concerns depends on the demographical and geopolitical aspects. As such, a common work process may not be applicable to all.

-

The nature of doing business and local laws can be as varied as the outlet’s location. Even language complexity can decide a contractor’s performance levels. Lack of a diversified work approach can reflect incorrect statistics.

-

Data collection from so many sources, spread in so many locations can be slow. This delays its analysis, hence spotting a problem and its corrective action will be delayed too.

-

The physical nature of cleaning work keeps the contractor engaged in the actual task, away from reporting methodologies. The situation is worse if reporting structure is still dependent on paperwork and physical interactions. It leads to slow and incorrect reporting.

So how Burger King overcame such challenges to ensure clean and hygienic kitchens?

Let us find out.

Like most QSRs (Quick Serving Restaurants), Burger King employs sequenced flow cooking that requires the ideal workflow organization. This includes professional care of the kitchen equipment. Steps for these are detailed to the minutest level, such as,

-

Fixtures and Shelves are clean and free of build-up.

-

Shelves clean and free of build-up

-

Sinks clean and free of build-up

-

Hand sink

-

3-compartment sink

-

-

-

Cooking Equipment is clean and free of build-up

-

Broiler and Hood

-

Fryers and Hood

-

Ovens

-

Toasters

-

Microwaves

-

Egg Cooker

-

And the list continues covering other points related to cleaning as per contract.

To ensure uninterrupted service, cleaning is done at night, when customers and employees are absent. Cleaning is carried out by professional service providers who partner with Burger King on a contract basis.

Cleaning process streamlined with QVALON

QVALON’s task management feature helped Burger King provide a dedicated task checklist to each cleaning service provider as per the contract with them. Some of the tasks mentioned in the checklist were common requirements of all outlets, and hence applicable to all service providers. While other tasks were as per the specific requirements of an outlet or region. QVALON’s ability to auto-generate tasks based on previous inspections and inspections helped Burger King in customizing task checklists for each cleaning contractor. These checklists were reflective of the needs of each outlet under the care of a cleaning service provider.

Task completion is inspected every morning before opening, by each outlet’s manager or supervisor. They are provided with QVALON’s inspection feature, through which they attest success or failure of each task mentioned in the checklist available with cleaning contractors. The ability to click photos within QVALON and to add comments on it allowed for more detailed and visual-based reporting. This also assisted them in describing actual in-store scenarios for quick and easy understanding.

These daily inspection reports are available with regional managers. They can view the most important statistics through their mobile devices, via QVALON app (Android and iOS). And detailed analytics are available to them on the web interface Through QVALON’s analytics, they find trends over a selected period of time. In case an outlet scores poorly in the inspection report, based on the analytics a regional manager quickly draws one of the following conclusions:

-

It was a one-off incident, or

-

A specific outlet is scoring poorly consistently, or

-

A specific outlet is scoring poorly inconsistently, or

-

A whole region is scoring poorly consistently, or

-

A whole region is scoring poorly inconsistently.

Accordingly, needed corrective action is taken. This is done speedily through the audio and video call feature available within QVALON. Hence, Burger Kings’ regional managers can quickly connect with concerned contractors, outlet supervisors, and outlet managers as needed without having to search for their contact details. Regional managers also share their suggestions and recommendation on images if they are part of inspection reports. This allows for quick corrective actions to ensure a great brand experience.

Since analytics highlight, if the underlying cause(s) for poor results in inspection reports are specific to one outlet or region, work processes are easily edited if needed on QVALON so that expected performance levels are maintained.

What results were achieved?

QVALON’s analytics helped Burger King recalculate the cost of services in their favor in the case of inconsistencies in the quality of services by contract cleaners. The basis of these calculations is eventually included as a clause in the revised contract agreement with the existing and new service providers.

Through QVALON, Burger King is able to break down its brand’s vision, principles, ethos, and skills into work processes. QVALON then shaped work processes into roles, responsibilities, and duties for all human resource hierarchies, specific to each level. This permitted quick communications and reporting.

QVALON also improved Burger King’s brand value among contractors as QVALON’s easy use, yet detailed features helped them have a clear understanding of their everyday tasks. QVALON eradicated dubious and inconclusive nature of,

-

Legal contract’s language,

-

Human conversations, and

-

Process training

Since everything is quantified and qualified through QAVLON, by Burger King and its contractors, there is no room for ambiguity for both entities. Although exact numbers are confidential, still, cleaner kitchens helped Burger King achieve a nine percent reduction in cleaning costs.

Inefficient contractors providing low-quality services consistently were identified. Appropriate assistance was provided to them to help them understand Burger King’s expectations regarding cleaning quality and protocols. If below-par performance continued then necessary steps were taken to uphold company standards. Analytics also helped Burger King in drafting new contracts which included a clause for recalculation of service cost in their favor, in case of inconsistent service quality.

The way ahead

The positive results achieved through QVALON’s assistance in Burger King’s kitchen cleaning methodologies have convinced Burger King’s management to set up the analytical processes tree to conduct more in-depth checks of the network branches.

Results achieved by Burger King through QVALON can also be accomplished by you. QVALON is available for every retail-based business, big or small. It can be personalized as per the exact requirements and structures of your business. Connect with us for a detailed demo and answers to all your queries.